Focus on CNC precision parts processing

Agile CNC milling service for prototyping and production parts. Get custom CNC milled parts of good quality for mechanical metal or plastic as fast as days.

➡3/4/3+2/5 CNC milling machines

➡World-class machines such as Hermle

➡Lead time as fast as 3 day

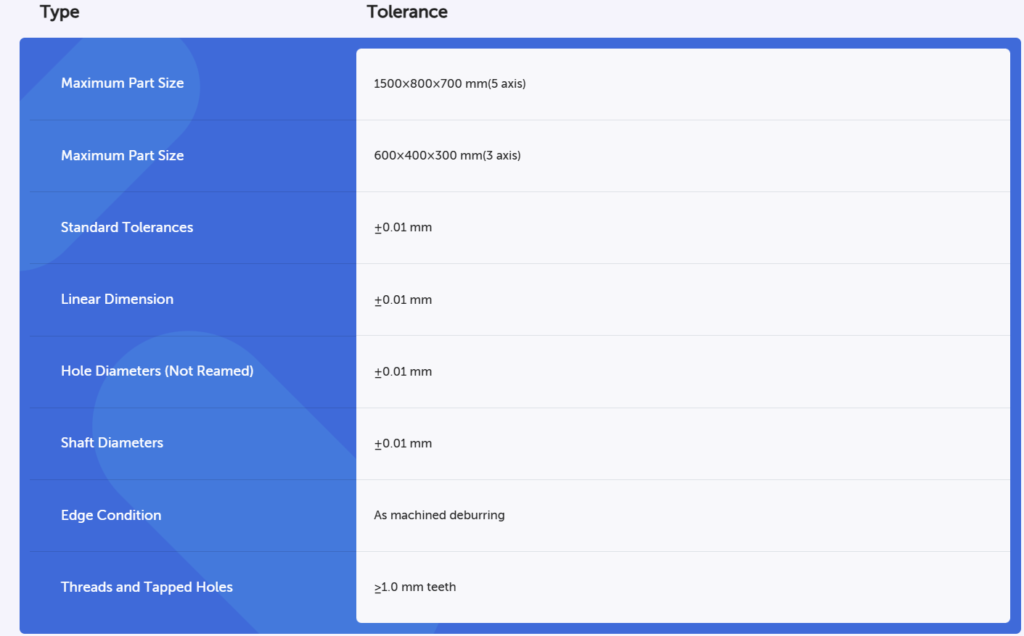

To satisfy customer with precision and accuracy, we introduce various kinds of equipment, including 3 axis, 3+2 axis, 4 axis, and full 5 axis CNC milling service. Unlike direct cooperation with other manufacturer suppliers, we have self-owned CNC milling centers from rapid prototyping to production parts. Thus, we have better control over product quality and delivery time. Now get a quote with us and bring your concept into reality with our robust CNC milling capability.

Discover surface finishing to eliminate machining marks, enhancing both functionality, aesthetics for superior-quality parts.

Just upload your 2D drawings or 3D models and you will get quote feedback in 24 hours. Our specialized engineers will analyze your design to avoid misunderstanding, communicate with you and offer an affordable price.

The responsible and rigorous attitude towards materials, machining technique, surface finishing and CMM testing guarantee the consistent quality from prototyping to production parts. We won’t bother to check the parts quality before delivery.

The introduce of advanced 5 axis CNC machining centers and professional quoters ensure the fast lead time. We set the priority for the arrangement of the order according to the requirements and order complexity.

For the sake of your benefits, every customer will have technical support to get in touch with us from quotation to delivery. You will get fast feedback for any question until it’s confirmed that you receive the satisfied parts.

Various and Robust CNC Milling Services

Zintilon’s rapid prototype service bridges the gap between product concept and market during the product development. Advanced CNC machines such as Hermle 5 axis cnc milling centers, multiple international certifications, and top-notch CMM inspection ensure the accuracy and details of the prototype, meeting high standards of quality requirements.

➡Advanced Technology: CNC, CMM inspection, elite engineers etc.

➡Quick Response: full support to ensure problem solved.

➡Customized service: customize precision machining solutions

Zintilon’s on-demand production solution provides customers with a modern, efficient and customer-oriented production solution through its flexibility, high quality standards by our robust supply network and self-owned CNC shop, strict quality control inspection, etc.

➡Reasonable planning: precision resource allocation to ensure quick cycle time.

➡Machining SOP : advanced technology and strict QC processes.

➡Flexible Production: from rapid prototyping (1-20pcs) to low-volume production (20-1000pcs).

Multi-axis milling, as the number of axes increases, the machining capacity is also enhanced accordingly, and more complex part designs can be processed. 5-axis CNC milling allows the largest machining range and flexibility, while 3-axis and 4-axis are relatively low.

3-axis CNC milling

4-axis CNC milling

5-axis CNC milling:

Table of Contents Precision Machining Overview Precision machining is a highly specialized…

Table of Contents Computer Numerical Control (CNC) machining is a manufacturing process…

What Are Tight Tolerances? In CNC machining, tight tolerances refer to the…

5 axis CNC machining represents a significant leap in manufacturing capabilities. Unlike…

CNC machining is a high-precision and versatile manufacturing process ideal for producing…